An aquarium compressor is a device for saturating the water with oxygen, which is contained in the air. This is the main function of this device. Basic, but not the only one.

Air bubbles rising up from the atomizer located at the bottom form a kind of so-called bubble elevator. This elevator draws the water with it, causing it to rise upwards. This contributes to faster mixing of water layers, equalization of temperature in all its layers.

In addition, the bubble elevator provides the operation of some internal filter designs.

The air bubbles bursting at the surface break down the bacterial and dust film, which also improves aeration.

Another auxiliary function, but by no means the last one for the observer, is the decorative effect. A fountain of small bubbles in its place can change the underwater landscape for the better beyond recognition.

So what kind of aerators are there?

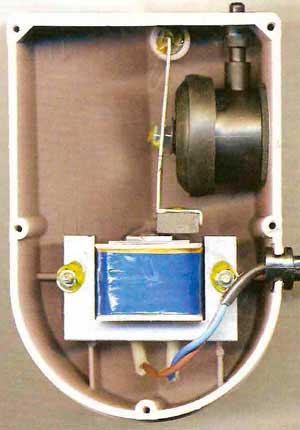

Today, most household compressors are vibrating machines. The principle of their operation is based on the fact that the alternating current of the electric network creates an alternating magnetic field around an electromagnet rigidly fixed inside the appliance. This alternating magnetic field acts on a permanent magnet located relative to the electromagnet in such a way that it is attracted by one pole of the electromagnet while the other pole repels it. When the polarity of the mains voltage changes, the position of the poles of the electromagnet also changes. As a result, the permanent magnet tends to move to another stable position. The cycle is then repeated.

It is not difficult to guess that the frequency of oscillation of the permanent magnet will be 50 Hz. In some models, due to design tricks, the frequency of oscillation is doubled to 100 Hz. The magnet is attached to a movable bracket, through which its vibrations are transmitted to a diaphragm made of elastic material. As a rule – rubber. By oscillating, the diaphragm creates increased and decreased pressure inside a small chamber with which it is hermetically connected. On the outer wall of the same chamber are two valves that allow air to flow in only one direction – outside the aerator to the socket leading to the aquarium.

Почему бесшумный компрессор – редкость?

Why did I dwell on the design of the vibratory compressor in more detail? It was necessary to understand one simple thing. The very principle of operation of this product is vibration. Vibration is nothing but a source of noise. There are no silent vibrating devices! There are models in which during the design the manufacturer has taken measures to reduce the noise that can be heard outside the device. But this naturally results in additional cost of the product. Sometimes it is so additional that you seriously have to decide either to put up with the noise or to invest additional money or to take measures to reduce the noise of a generally not bad, though not expensive, but noisy compressor (which will be discussed in one of the next articles).

Piston compressor for aquarium

The vibration mechanism is not the only way to create aerators. Increased air pressure can be created by means of a piston pump driven by an electric motor. The rotary motion of the motor shaft is converted into an oscillating motion by means of a special eccentric. This design can be very powerful. Its power can be enough for any aquarium household. In addition to increased power, such an aerator is also silent.

But the presence of an electric motor, a high-quality pump, as well as a reducer necessary to reduce the speed to acceptable pump speeds makes such a design is expensive and not cost-effective in the hobby segment of the market. More often such compressors are positioned as professional or for pond aeration. It is true that compressors for pond aeration have a higher frequency of movement of the pump piston. So these pumps are rarely quiet either. But for a pond, this may not be critical.

An intermediate variant between the two above described constructions is a compressor for aquarium, in which the electric motor through the eccentric causes the elastic diaphragm to oscillate, as in the first design. But the feasibility of such an arrangement, in my opinion, is questionable. The motor makes the system more expensive, and for effective operation of the diaphragm its oscillations should have a high enough frequency. That is, the system becomes more expensive, but it does not get rid of noise, and the power does not increase. Such construction of the device can be justified only in case of battery power supply, if there is no desire or possibility to build a converter of constant voltage to alternating voltage.

Self-contained compressors for aquariums

Here we have smoothly moved on to the next whole group of aerators – battery-powered mobile devices. They are necessary when it is necessary to keep a significant number of fish for a long time in a limited volume away from the power grid. The simplest examples are selling fish at the market on a non-electrified tray. Prolonged transportation of fish. In the latter case, it is possible, however, to connect to the on-board network of the car. But for this you will need either a 12\220V or 24\220V converter. Or you need a compressor with an input operating voltage equal to the on-board voltage of the car.

Battery compressors can be either vibration or electric motor operated. When using them, it should be remembered that the choke, which in general case is, and the electromagnet and motor windings consume quite a lot of energy. One set of batteries for most designs is enough for 4-6 hours of continuous operation. There are, of course, some pleasant exceptions.

Pump as a compressor for the aquarium

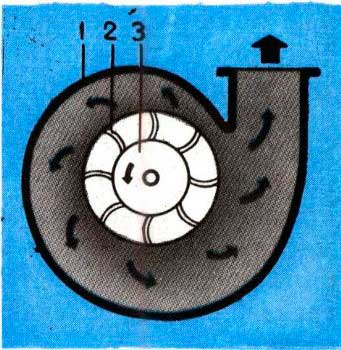

An aquarium pump can also play the role of an aerator. Many models of internal filters on the output socket of the pump has a branch for connecting an air pipe, through which a rapid current of water is sucked in air and ejected from the socket, broken into many small bubbles. The pumps have no strongly vibrating parts. They themselves are underwater and are also a centrifugal pump with a collectorless electric motor. Such devices effectively mix water, aerate and filter it. Other advantages should include the quietness of the mechanism. True here in the foreground comes to the forefront sometimes excessive noise of bursting bubbles. But unlike the monotonous humming of an electromagnet, it can even be pleasant.

To such a barrel of honey I can’t help but add a spoonful of tar. The water jet from the device is too strong for most small species. Use for spawning or nursery aquarium is not acceptable at all. Filters of these products require the same attention and regular cleaning as filters of other devices only more often. Due to the high pumping speed, filtrate may begin to eject from the filter.

The outlet stream can be directed vertically downwards using special adapters. Then the current speed will be reduced and small fish will not have to fight with the mountain stream all the time.

In addition, this type of device is quite bulky and relatively difficult to disguise.

There are similar or rather the same designs only without a compartment with a foam filter and are called – internal compressor for aquarium. The advantages and disadvantages are the same as for the design with filter.

Compressor for aquarium without electricity

Electrified devices are not the only way to aerate water.

Thirty years ago, aquarium fish sellers at the market widely used a construction made of a soccer ball or bicycle wheel tube. It was inflated with air using a hand-held bicycle pump, which was connected through a special tee. The third branch of the tee was connected to the hose going to the aquarium. During the inflation of the chamber, the hose was clamped with a clamp, which was used to regulate the speed of air supply.

Of course, such a construction is not suitable for the role of the main device today, but it can be used for one-time long-term transportation of fish. The simplicity and cheapness of the device and the fact that it can be assembled from improvised materials, which can then be used for their intended purpose. By the way, if you do not use the camera itself, but a ball with a leather shell or a whole bicycle wheel, they can be pumped with air under high pressure. Then it will be enough for a greater amount of time. However, in this case on the hose going to the aquarium, be sure to install a control valve, which will be used to regulate the speed of air supply.

Oxidizer instead of an aquarium compressor

Another way to saturate water with dissolved oxygen is the use of so-called oxidizers. The principle of their operation is that in its reactor under the action of a special catalyst decomposes hydrogen peroxide into water and oxygen. No external power supply is required. There is no noise. Hydrogen peroxide is heavier than water and so theoretically it cannot escape from the reactor. One refill of hydrogen peroxide according to the manufacturer is enough for 2 – 4 weeks of work in a capital-liter aquarium. You can forget about the bubble elevator.

Mix water this device also will not. In addition, hydrogen peroxide is the strongest oxidizer capable of killing both pathogens and useful microorganisms, it will kill it in direct contact with fish and plants inflicting them chemical burns. But this is a force majeure. If used properly, the device should be safe. But I refrain from using it for now.

So, to date, the most acceptable aerator for indoor aquarium farming in terms of price/quality ratio is a vibrating compressor with power supply. You can look for one with a reduced noise level. It should only be borne in mind that the noise characteristics of such devices are very individual for each individual copy. Even in a device for which special technologies for noise reduction are declared, its level may not be acceptable to you, but you will still pay money for these “high” technologies. It is better to check the noise level when buying an appliance. It is better to check it, of course, in a quiet room.

Some tips for choosing an aerator

When choosing how to aerate the aquarium, the capacity of the product should be taken into account. This is the number of liters of air that the compressor can transfer per hour. The minimum required capacity for an aquarium without a biofilter is 0.5-0.7 liters/hour for each liter of water in your artificial lake. If you have a 100-liter aquarium, the compressor should provide a minimum capacity of 0.5×100=50l/hour. If your aquarium is equipped with a biofilter, not equipped with an active system of air supply inside it, you can safely multiply the above value by 1.5 or even 2.

I think this is the end of this review. With an understanding of aeration systems and aquarium compressor designs, it will be easier for you to choose exactly what you need.